Building a winning lamination program

Building a Winning Lamination Program!

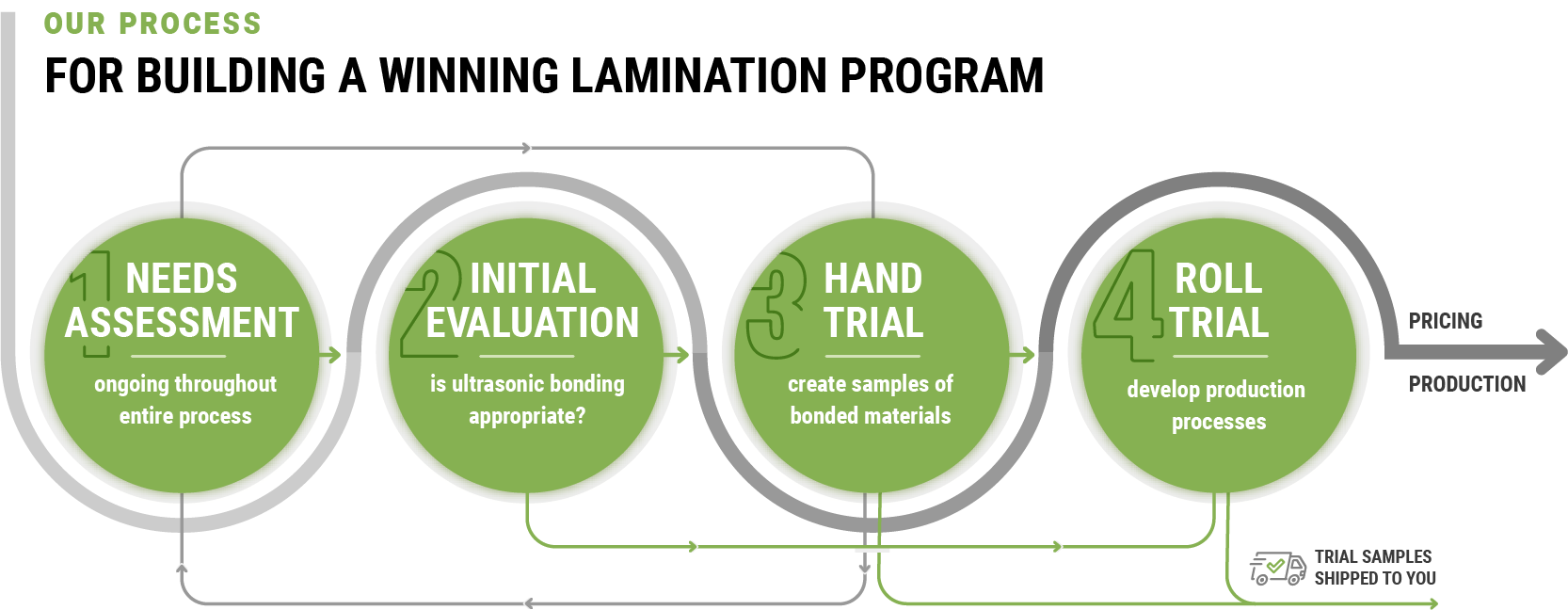

Every textile laminating program we have with our customers is unique. Although the path through program development takes many twists and turns, there are a number of specific process stages that are common and vital to achieving a strong outcome.

So, whether it is by telephone, email, or several tools available on our website, please use whatever means you find most comfortable to begin the dialogue!

1: Once an inquiry is qualified, we launch compilation of a Needs Assessment.

We view the Needs Assessment not as a document, but as an ongoing process that evolves over time to define and support a laminating program as completely as possible. It is important that we receive as much information as possible in as much detail as possible about your program early in the discussions. As time goes on, more layers and details of information are needed.

2: Utilizing basic information early in the discussion, we conduct an Initial Evaluation

An Initial Evaluation will determine if ultrasonic bonding is an appropriate laminating technology. Our recommendation after this initial evaluation is completed would be either to move to a Hand Trial or to stop any further work in cases where ultrasonic bonding would not work for your laminate. Occasionally, we may recommend moving directly to a roll trial.

In most cases, it is during these early discussions where we will execute a Mutual Non-Disclosure Agreement with the customer or prospect.

3: Conduct a Hand Trial

The primary goal of the Hand Trial is to determine if the laminate design you have created is bondable using ultrasonics. The completed samples will enable you to see the bonding pattern on your materials package. We run all hand trials directly on our production equipment, not on laboratory research and development rigs.

A typical hand trial is executed at No Charge and results in delivery to you of between 3 to 6 samples run on a single roll pattern. Each hand trial sample is labeled with date of the trial, the customer’s name, the materials involved, and the bonding technology used. Beckmann Converting has eight different roll patterns available that are appropriate for different materials and different laminate end uses. Our staff will work with you to determine which roll pattern or patterns may be best to use. You can refer to the Virtual Swatchbook on the Beckmann Converting website for more details about each of the roll patterns available.

Once agreed upon, the hand trial would be run the next time the desired roll pattern is mounted in a laminating machine. For all hand trials, we ask for a UPS or Fedex account number along with guidance as to what level of expedite service to use to ship the hand trial samples to you when they are completed.

4: Conduct a Roll Trial

The primary goal of a Roll Trial is to develop the initial ultrasonic laminating process for a specific laminate package of materials so that production runs can begin. Most roll trials require a minimum of 500 lyds to 1,000 lyds of each of the raw materials. As many details as possible about the “final” finished laminate are added to the program Needs Assessment and are incorporated into the plan.

At startup, the machine speeds are kept very slow and the focus is placed on achieving a high quality finished laminate. Once accomplished, machine speed is increased and machine setting adjustments made until an optimal, steady state laminating condition is confirmed. Beckmann Converting’s technical team provides a detailed report on the outcomes and challenges of the roll trial and whether the program is ready to move into production runs.

Most roll trials generate adequate data and information for Beckmann Converting to provide pricing quotations to customers for initial production runs. See the Pricing document for more details on pricing of laminating services at Beckmann Converting.

Transitioning To Production

At some point in this process, the laminating program is ready for Production runs. A Specification for the laminating is agreed upon, the customer formally notifies Beckmann Converting that the finished laminate in the last run meets the specification and their expectations, and a unique “Style #” is assigned to the laminate.

The new laminate is now an official product in the eyes of Beckmann Converting and can be ordered anytime by the customer for production.